VDS-200 Series – Vertical Tablet Dedusters

The next generation of tablet dedusting and conveying technology.

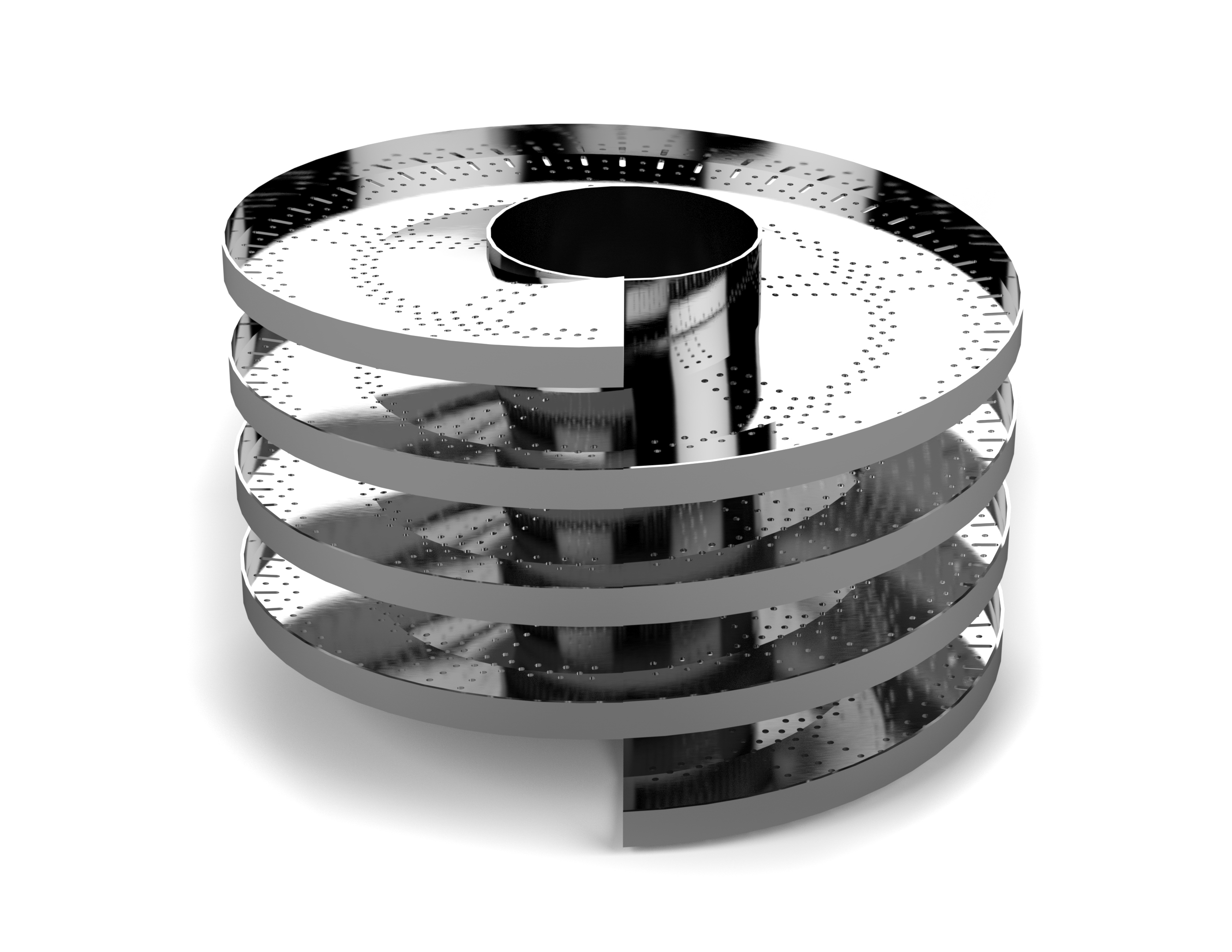

The VDS-200 Series represents the latest advancement in vertical tablet dedusting for large-scale pharmaceutical and nutraceutical production. Built on Cropharm’s proven design platform, it offers superior dust removal efficiency, increased throughput, and seamless integration with modern tablet press lines.

How it Works:

Tablets are conveyed upward through a precision-engineered segmentable stainless-steel spiral using controlled vibration. As they travel, dust and loose particles are continuously extracted through a vacuum channel, ensuring clean, polished tablets without surface damage.

Upward Conveying Advantage:

The VDS-200’s vertical conveying motion provides a significant elevation gain, allowing direct connection to downstream inspection, metal detection, or packaging systems. This efficient layout eliminates the need for additional transfer equipment and supports larger final collection bins—optimizing both floor space and process flow.

Key Features

- Digital vibration controller for precise, continuously variable speed control

- Adjustable inlet height for integration flexibility across different tablet presses

- Modular design supports multiple tower heights on a single base

- High performance design average output of 1,000,000 tablets/hour (depending on shape/size)

- Stainless steel SS316L construction for hygienic operation and durability

- Optional integrated metal detector for complete in-line dedusting and inspection

Applications

Perfect for pharmaceutical laboratories and production facilities requiring clean, dust-free tablets for further processing or packaging.

VDS-200S

VDS-200M

VDS-200T

VDS-200XT

Accessories

Enhance your tablet dedusting operations with our range of compatible accessories and components.

Deduster Segment